Aluminum Circle Price

- Home

- Aluminum Circle Price

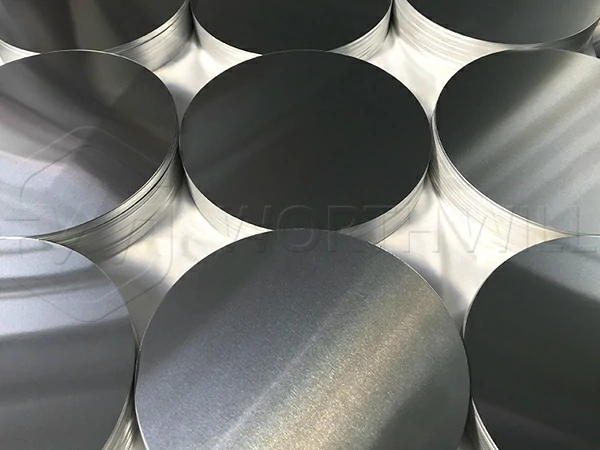

Aluminum circle price help you make informed decisions for your specific needs. If you’re in the market for aluminum circles, it’s essential to understand the factors that influence price and quality.

The Importance of Corrosion Resistance

Corrosion resistance is a critical factor when choosing aluminum circles, especially for applications where exposure to moisture or harsh environments is a concern. Aluminum naturally forms a thin oxide layer on its surface, which provides a degree of corrosion resistance. However, for enhanced protection, aluminum circles can undergo various surface treatments, such as anodizing or coating with a protective layer.

Low-Priced Aluminum Circles

Alloy Composition

The choice of aluminum alloy significantly impacts the price of aluminum circles. Commonly used alloys for circles include 1050, 1060, 1070, and 1100. These alloys are more affordable than others like 3003 or 5052 due to their lower levels of additional elements, such as manganese or magnesium.

Thickness and Size

The thickness and size of aluminum circles also affect their price. Smaller, thinner circles are generally more cost-effective. However, consider your specific application’s requirements to ensure you select the right dimensions for your needs.

Production Technique

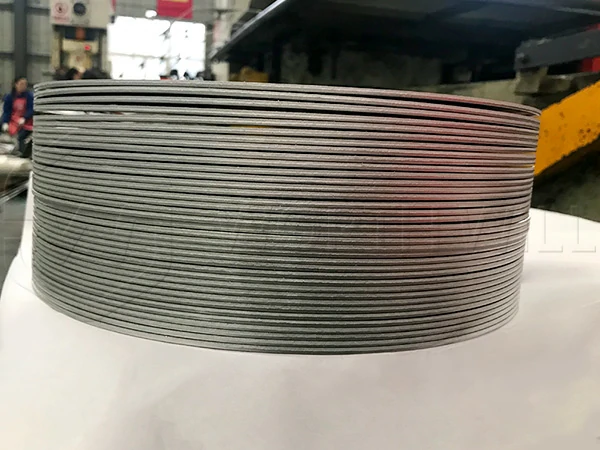

The method used to produce aluminum circles can influence their price. Circles produced through processes like cold rolling or deep drawing may be more expensive due to the precision and material loss involved. Hot rolling or stamping processes can yield lower-priced options.

Supplier and Location

The location of the supplier can impact prices, as transportation costs and local market conditions come into play. It’s essential to balance cost savings with the reputation and reliability of the supplier.

Corrosion-Resistant Aluminum Circles

Surface Treatment

For applications requiring exceptional corrosion resistance, consider aluminum circles that have undergone surface treatments like anodizing, which thickens the natural oxide layer, or coating with protective materials. These treatments enhance the circle’s resistance to moisture, chemicals, and environmental factors.

Alloy Selection

Certain aluminum alloys, such as 3003 and 5052, offer superior corrosion resistance compared to others. These alloys contain elements like manganese and chromium that provide enhanced protection against rust and corrosion.

Applications of Aluminum Circles

Aluminum circles find applications in various industries:

Cookware: Commonly used as the base of pots, pans, and other cooking utensils due to their excellent heat distribution properties.

Automotive: Used in wheel rims, engine parts, and body panels, where both corrosion resistance and lightweight characteristics are essential.

Electronics: Aluminum circles serve as substrates for electronic components, such as LED lights and PCBs, due to their thermal conductivity and electrical properties.

Packaging: Used in the production of caps, closures, and containers for food and beverage packaging.