Aluminium Circle Factory

Producing High-Quality Aluminum Circles for Diverse Industries

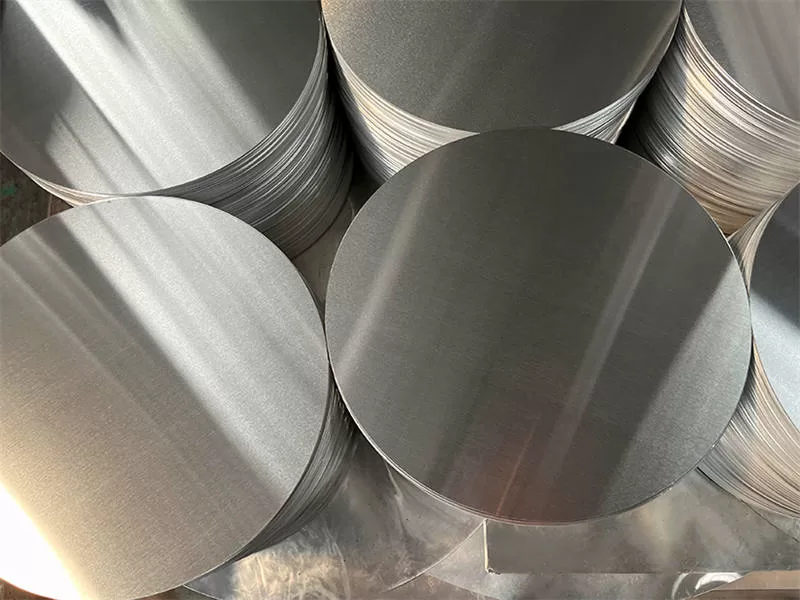

In the vast landscape of metal manufacturing, the aluminium circle factory stands as a crucial hub. These versatile metal components are fundamental to countless products we use daily, from kitchenware to industrial applications.

What is an Aluminum Circle?

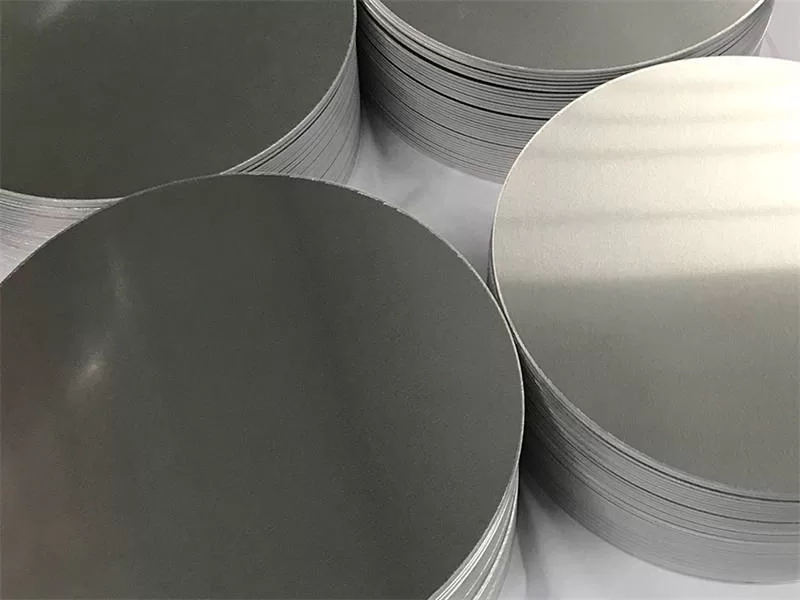

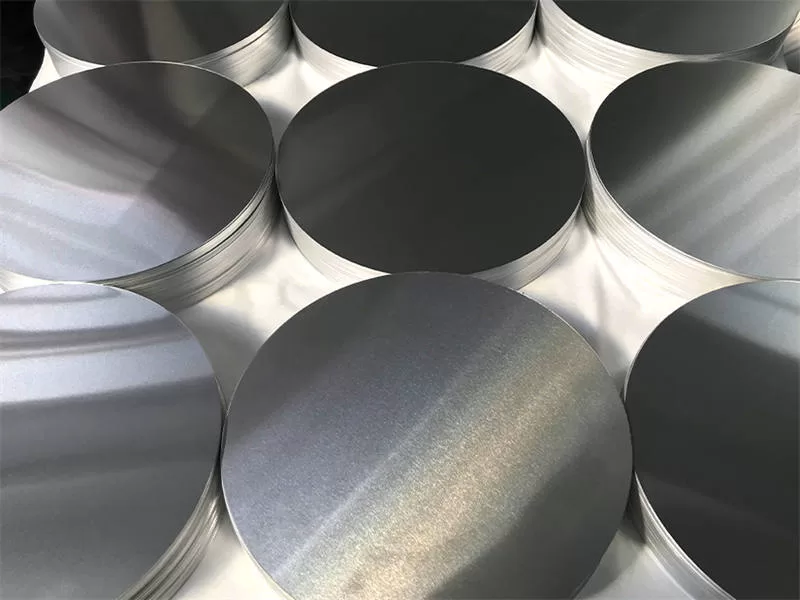

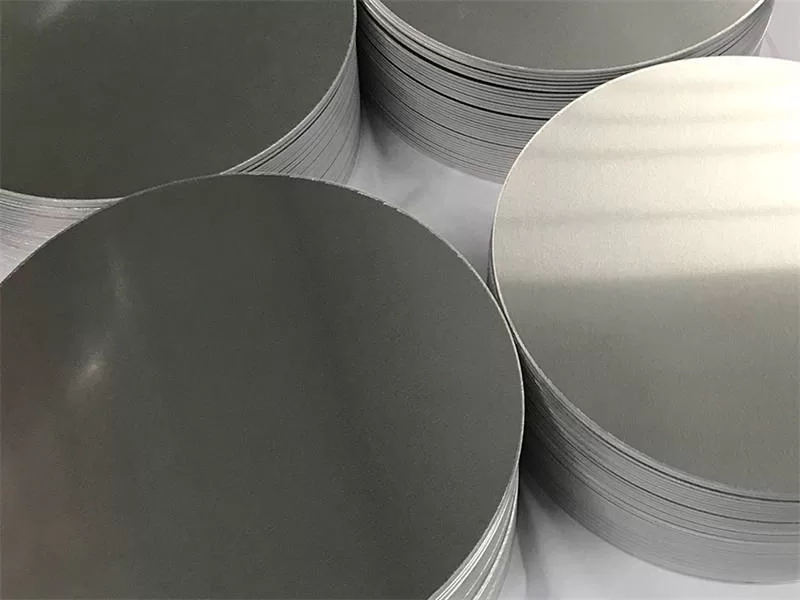

An aluminum circle is simply a flat, round piece of aluminum sheet or plate. Its uniform shape and consistent properties make it an ideal starting material for deep drawing, spinning, and pressing techniques. The quality of the initial aluminum circle directly impacts the final product’s performance and appearance, making the selection of a reliable aluminium circle factory paramount.

The Role of an Aluminium Circle Factory

An aluminium circle factory is more than just a production plant; it’s a center of expertise. Its primary role is to transform raw aluminum coils or sheets into precise, circular blanks tailored to customer specifications. This involves a series of sophisticated processes, from material selection to cutting, annealing, and final inspection. A reputable aluminium circle manufacturer ensures that every disc meets the highest standards of dimensional accuracy, surface finish, and material integrity.

Types of Aluminium Circles Produced by a Factory

A modern aluminium circle factory produces a wide array of aluminum circles, categorized primarily by alloy, temper, and dimensions. The choice of type depends heavily on the intended application, with different alloys offering distinct properties like formability, strength, and corrosion resistance.

| Category | Description | Common Alloys (Examples) | Common Tempers (Examples) |

|---|---|---|---|

| Common Alloys | These alloys are chosen for their excellent formability and surface finish, often used for general-purpose applications. | 1050, 1060, 1070, 1100 (Pure Aluminum Series) | O (Annealed/Soft), H12, H14, H18 |

| Manganese Alloys | Known for good strength and formability, with better corrosion resistance than pure aluminum. Widely used for cookware. | 3003, 3004, 3105 | O, H12, H14, H24 |

| Magnesium Alloys | Offer higher strength and excellent corrosion resistance, especially in marine environments. Suitable for more demanding applications. | 5052, 5083, 5754 | O, H32, H34, H111 |

Common Specifications for Aluminum Circles

An aluminium circle factory can produce discs within a wide range of specifications to meet diverse industrial needs.

| Specification | Typical Range | Notes |

|---|---|---|

| Thickness | 0.3 mm to 8.0 mm (0.012 inches to 0.315 inches) | Thinner for lightweight applications like lighting, thicker for heavy-duty cookware or industrial parts. |

| Diameter | 50 mm to 1200 mm (2 inches to 47 inches), sometimes larger for specialized orders | The range can vary significantly based on the factory’s machinery and customer requirements. |

| Surface | Bright, Mill Finish, Anodized Quality | Mill finish is standard; bright is polished; anodized quality ensures suitability for further surface treatment. |

Manufacturing Process at an Aluminium Circle Factory

An efficient aluminium circle factory typically follows these key steps:

- Raw Material Sourcing: High-grade aluminum coils or ingots.

- Melting & Casting (if from ingots): Raw aluminum is melted and cast into large slabs or continuously cast into coils.

- Hot Rolling: Slabs are heated and passed through rollers to reduce thickness and refine grain structure.

- Cold Rolling: The material is further rolled at room temperature to achieve precise thickness.

- Punching/Stamping: Large presses with specialized dies cut out the circular blanks from the aluminum coils or sheets. This step requires high precision to minimize waste and ensure consistent circle diameters.

- Annealing: For certain tempers (like “O” or soft temper), circles undergo an annealing process in a furnace. This heat treatment softens the metal, making it more ductile and suitable for deep drawing without cracking.

- Deburring/Edge Finishing: Edges are often smoothed to remove any burrs from the cutting process, ensuring safety and quality.

- Inspection: Each aluminum circle undergoes rigorous quality checks for dimensions, surface defects, and material properties.

- Packaging: Finished circles are stacked and packaged, often with interleaved paper or protective film.

Quality Control in an Aluminium Circle Factory

Quality is paramount for any reputable aluminium circle factory.

- Material Composition Analysis: Using spectrometers to verify the exact chemical composition of the aluminum alloy.

- Dimensional Accuracy Checks: Precise measurements of thickness, diameter, and flatness.

- Surface Quality Inspection: Visual and automated checks for scratches, stains, and other surface imperfections.

- Mechanical Property Testing: Tensile strength, yield strength, and elongation tests to ensure the material performs as expected during subsequent processing.

- Earring Test:

Advantages of Sourcing from a Dedicated Aluminium Circle Factory

Choosing a specialized aluminium circle factory offers distinct benefits compared to general metal suppliers.

| Advantage | Description |

|---|---|

| Specialization & Expertise | Dedicated factories possess in-depth knowledge and experience solely focused on aluminium circles, leading to superior product quality and efficiency. |

| Consistent Quality | State-of-the-art machinery and rigorous quality control ensure that every aluminum disc meets precise specifications, providing uniformity across large orders. |

| Cost-Effectiveness | High-volume production and optimized processes allow a specialized aluminium circle manufacturer to offer competitive pricing without compromising quality. |

| Customization Capabilities | Factories can produce aluminum blanks in a wide range of alloys, tempers, thicknesses, and diameters to meet unique customer requirements and specific application needs. |

| Reliable Supply Chain | Established factories have robust supply chains for raw materials and efficient logistics for timely delivery, ensuring consistent availability for your production schedule. |

| Technical Support | Expert teams can provide valuable technical advice regarding material selection, process optimization, and troubleshooting for your specific applications. |

Common Applications of Aluminium Circles

The versatility of aluminium circles makes them indispensable across a multitude of industries. Some key applications include:

- Cookware: The most common application, used for producing pots, pans, pressure cookers, kettles, and other kitchen utensils. Aluminum’s excellent heat conductivity is ideal here.

- Lighting Industry: Used for manufacturing lampshades, lighting reflectors, downlights, and various decorative lighting components due to its reflective properties and formability.

- Road Signs & Traffic Signs: The lightweight and corrosion-resistant nature of aluminum makes aluminum blanks perfect for durable outdoor signage.

- Cap Closures: Used extensively in the packaging industry for bottle caps, jar lids, and aerosol cans.

- Electronic Components: Certain aluminium discs find use in electronic enclosures, heat sinks, and other parts.

- HVAC Systems: Components for heating, ventilation, and air conditioning units.

- Automotive Parts: Smaller stamped parts and decorative elements.

- Arts & Crafts: Hobbyists and artists use them for various creative projects.

Choosing the Right Aluminium Circle Factory

When seeking a reliable partner for your aluminium circle needs, consider the following:

- Certifications: Look for factories with ISO certifications (e.g., ISO 9001) for quality management.

- Experience & Reputation: Choose a factory with a proven track track record and positive customer reviews.

- Production Capacity: Ensure the factory can meet your volume requirements, both now and in the future.

- Customization Options: Verify their ability to produce circles according to your precise specifications.

- Quality Control Procedures: Inquire about their internal quality testing and inspection protocols.

- Customer Service & Communication: A responsive and helpful team is vital for smooth transactions.

FAQ Section

Q: What’s the difference between 1050 and 3003 alloy circles?

A: 1050 is softer (better for deep drawing), while 3003 has higher strength (ideal for cookware).

Q: Can I get circles with center holes?

A: Yes, most factories offer punched/perforated circles.

Q: How are circles priced?

A: By weight + processing fee. Thinner circles cost more per kg due to rolling complexity.