What is Aluminum Circle?

Aluminum circles are a versatile and essential component in various industries, particularly in the manufacturing and cookware sectors. These circular pieces of aluminum have a wide range of applications due to their excellent properties and adaptability.

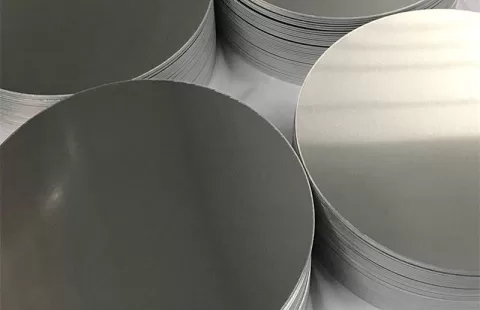

What is an Aluminum Circle?

An aluminum circle, also known as an aluminum disc or aluminum round sheet. It is a flat piece of aluminum that is shaped like a circle. These circles are typically made from aluminum alloy sheets. Through a process called blanking or stamping. Aluminum circles come in various sizes and thicknesses. And they are popular for their exceptional strength, corrosion resistance, and versatility.

Uses of Aluminum Circles

Cookware: One of the most common applications of aluminum circles is in the production of cookware, such as pots, pans, and baking sheets. Aluminum’s excellent heat conductivity ensures even cooking and reduces hot spots. There is a preferred choice for cookware manufacturers.

Lighting Industry: Used in the manufacturing of reflectors and lampshades due to their reflective properties. They help in directing and enhancing the light output of lamps and fixtures.

Automotive Parts: Used in the automotive industry to create various components, including wheel covers, fuel tanks, and hubcaps. Their lightweight nature helps reduce the overall weight of vehicles, improving fuel efficiency.

Signage and Nameplates: The durability and corrosion resistance of aluminum make it a popular choice for outdoor signage, nameplates, and labels. It can withstand exposure to harsh weather conditions.

Aerospace: Utilized for manufacturing aircraft parts and components, thanks to their lightweight properties and high strength-to-weight ratio.

Electrical Appliances: Used in the production of electrical appliances like rice cookers and pressure cookers due to their excellent heat distribution capabilities.

Advantages of Aluminum Circles

Lightweight: Aluminum is exceptionally lightweight, making it easy to handle and transport. This is particularly important in industries where weight is a critical factor, such as aerospace and automotive.

Corrosion Resistance: Aluminum has natural corrosion resistance, which makes it an ideal choice for outdoor and marine applications.

High Thermal Conductivity: Aluminum circles distribute heat evenly, which is essential for cooking utensils and heat exchangers.

Malleability: Aluminum is highly malleable, allowing it to be formed into various shapes and sizes without losing its structural integrity.

Recyclability: Aluminum is 100% recyclable, making it an environmentally friendly choice. Recycling aluminum consumes significantly less energy than producing it from raw materials.

Selecting the Right Aluminum Circle

When choosing an aluminum circle for your specific application, consider the following factors:

Alloy: Different aluminum alloys offer varying properties. Select the alloy that best suits your application, whether it’s for cookware, signage, or aerospace components.

Thickness: The thickness of the aluminum circle will affect its strength and durability. Ensure it meets the requirements of your project.

Diameter: Choose the appropriate diameter to match the intended use and dimensions of your product.

Surface Finish: Decide whether you need a smooth or textured surface, depending on the aesthetic and functional requirements.