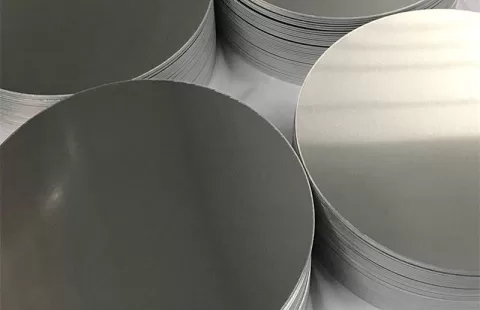

Deep Drawing Aluminum Circle 1050 1060 1100

Deep drawing aluminum circles are essential starting materials for creating a vast array of seamless, hollow, and complex-shaped metal products. When precision and formability are paramount, aluminum circles made from 1050, 1060, and 1100 alloys stand out as top choices.

What is Deep Drawing and Why These Alloys?

Deep drawing is a sheet metal forming process used to create three-dimensional parts from a flat sheet metal blank, like an aluminum circle, by drawing it into a die.

The success of deep drawing heavily relies on the material’s ability to undergo significant plastic deformation without fracturing. Aluminum alloys 1050, 1060, and 1100 are ideal for this process due to their:

- High Purity: These are commercially pure aluminum alloys (typically over 99% aluminum), meaning they have very few alloying elements that could hinder ductility.

- Excellent Formability (Ductility): Stretched and shaped extensively without cracking, allowing for complex and deep draws.

- Good Corrosion Resistance: Naturally resistant to rust, especially when formed into finished products.

- Superior Surface Finish: They provide a smooth, clean surface that is ideal for polishing, anodizing, or painting after forming.

Key Characteristics of 1050, 1060, and 1100 Aluminum Alloys

While all three are commercially pure aluminum, there are subtle differences that make each suitable for specific deep drawing needs:

- Aluminum Circle 1050:

- Purity: Minimum 99.5% Aluminum.

- Characteristics: Excellent ductility, high workability, good thermal conductivity.

- Common Tempers: O (annealed) is most common for deep drawing due to maximum softness.

- Aluminum Circle 1060:

- Purity: Minimum 99.6% Aluminum.

- Characteristics: Very similar to 1050 but with slightly higher purity, offering marginally better formability and corrosion resistance.

- Common Tempers: O (annealed).

- Aluminum Circle 1100:

- Purity: Minimum 99.0% Aluminum (with small additions of copper, iron, silicon, etc., to improve strength slightly).

- Characteristics: Good formability, slightly stronger than 1050 and 1060, excellent corrosion resistance, and good electrical/thermal conductivity.

- Common Tempers: O (annealed), H12, H14 (partially strain-hardened for specific forming).

Classification of Deep Drawing Aluminum Circles

Alloy Types: 1050, 1060, 1100

1050 Aluminum Circle

- Purity: ≥ 99.5%

- Features: Excellent corrosion resistance, high ductility

- Use: Cookware, lampshades

1060 Aluminum Circle

- Purity: ≥ 99.6%

- Features: Very good elongation, smooth surface

- Use: Deep drawing utensils, kitchen pots

1100 Aluminum Circle

- Purity: ≥ 99%

- Features: Better strength than 1050/1060, still ductile

- Use: Industrial parts, cookware, decorative products

Table 3: Alloy Comparison

| Alloy | Purity (%) | Strength | Ductility | Common Use |

|---|---|---|---|---|

| 1050 | 99.5 | Low | High | Cookware, lampshades |

| 1060 | 99.6 | Low | Very High | Pots, utensils, reflectors |

| 1100 | 99.0 | Medium | Good | Industrial, cookware |

Deep drawing aluminum circles are primarily classified by their alloy, temper, and surface condition, which all impact their suitability for specific forming operations.

- By Alloy Type:

- 1050 Aluminum Circle: Best for maximum ductility.

- 1060 Aluminum Circle: Slightly higher purity, excellent formability.

- 1100 Aluminum Circle: Slightly stronger, good all-around performance for deep drawing.

- By Temper:

- “O” Temper (Annealed): This is the most common and preferred temper for deep drawing, as the material is in its softest, most ductile state, allowing for maximum deformation without cracking.

- “H” Tempers (e.g., H12, H14): These are strain-hardened tempers that offer increased strength. While possible to deep draw, they have reduced ductility compared to the “O” temper, limiting the severity of the draw.

- By Surface Finish:

- Mill Finish: The natural surface finish as it comes off the rolling mill.

- Bright Finish: A smoother, more reflective surface often achieved through specific rolling processes, ideal for applications requiring a lustrous appearance.

- Other Finishes: Can include brushed or matte, depending on aesthetic requirements.

Thickness and Diameter Specifications for Deep Drawing Aluminum Circles

The dimensions of deep drawing aluminum circles are crucial and must be precisely controlled to ensure successful forming. Manufacturers offer a wide range of specifications to meet diverse industry needs.

Table of Typical Specifications for Deep Drawing Aluminum Circles:

| Specification Type | Range / Common Values | Notes on Application |

|---|---|---|

| Alloy | 1050, 1060, 1100 | High-purity, excellent for deep drawing due to ductility. |

| Temper | O (Annealed) | Essential for maximum formability in deep drawing. |

| Thickness (mm) | 0.3 mm – 6.0 mm | Common for cookware, lighting, and general fabrication. |

| Diameter (mm) | 50 mm – 1200 mm (2 inches – 48 inches) | Varies greatly based on the size of the final drawn part. |

| Tolerance (mm) | +/- 0.02 mm to +/- 0.5 mm | Critical for consistent deep drawing results. |

| Surface Finish | Mill Finish, Bright Finish | Depending on end-use aesthetics (e.g., polishing, coating). |

Note: Custom sizes and tolerances are often available from suppliers to meet specific project requirements.

Packaging of Deep Drawing Aluminum Circles

Proper packaging of deep drawing aluminum circles is vital to protect them from physical damage, moisture, and contamination during transit and storage. Any surface defect or deformation can compromise the deep drawing process and the quality of the final product.

Standard packaging methods include:

- Protective Layers: Circles are typically interleaved with protective paper or film to prevent scratching between layers.

- Wooden Pallets: Stacks of circles are securely placed on sturdy wooden pallets, often fumigated for international shipping.

- Waterproof Wrapping: The entire stack is wrapped in waterproof paper, plastic film, or desiccant-infused bags to prevent moisture damage and oxidation.

- Steel or Plastic Strapping: Strong bands secure the circles to the pallet, preventing movement and ensuring stability.

- Wooden Crates: For smaller, high-value, or sensitive batches, full wooden crates may be used for maximum protection.

Effective packaging guarantees that the deep drawing aluminum circles 1050 1060 1100 arrive at your facility in pristine condition, ready for processing.

Applications of Deep Drawing Aluminum Circle 1050 1060 1100

The exceptional formability and other beneficial properties of deep drawing aluminum circles from 1050, 1060, and 1100 alloys make them indispensable across numerous industries:

- Cookware:

- Pots, pans, and frying pans.

- Pressure cookers and rice cookers.

- Baking molds and trays.

- Lighting Industry:

- Lamp reflectors and shades.

- LED light housings.

- Street light fixtures.

- Automotive Parts:

- Filter housings.

- Oil caps and certain fluid reservoirs.

- Brake components (e.g., master cylinder reservoirs).

- Electrical Appliances:

- Electric kettle bodies.

- Washing machine parts.

- Vacuum cleaner components.

- Construction:

- HVAC duct components.

- Ventilation parts.

- Packaging:

- Aerosol cans (though often higher strength alloys are used for cans themselves, these are used for components).

- Food containers and lids.

- Other Industrial Uses:

- Capacitor cases.

- Heat exchangers.

- Chemical apparatus components.

Advantages of Using Deep Drawing Aluminum Circle 1050 1060 1100

Opting for these specific deep drawing aluminum circles offers significant advantages:

- High Ductility: Enables complex shapes with excellent formability.

- Lightweight: Reduces the overall weight of final products.

- Corrosion Resistance: Provides long-lasting performance, especially for cookware and outdoor applications.

- Non-Toxic & Food Grade: Safe for food contact, making them ideal for cookware.

- Excellent Thermal Conductivity: Efficient for heating applications (cookware) and heat dissipation (lighting).

- Recyclability: Aluminum is 100% recyclable, supporting sustainable manufacturing practices.

- Cost-Effective: Often offers a good balance of performance and material cost for deep drawn parts.

FAQ

Q: What is the maximum drawing depth achievable?

A: Typically 2-3 times the diameter for these alloys, depending on thickness.

Q: Can these circles be annealed after drawing?

A: Yes, annealing can be performed to relieve stresses after deep drawing.

Q: What surface treatments are available?

A: Anodizing, polishing, painting, and coating can be applied after drawing.

Q: Are custom sizes available?

A: Yes, custom diameters and thicknesses can be produced.

Q: What is the typical MOQ?

A: Usually 1-2 tons, depending on specifications.